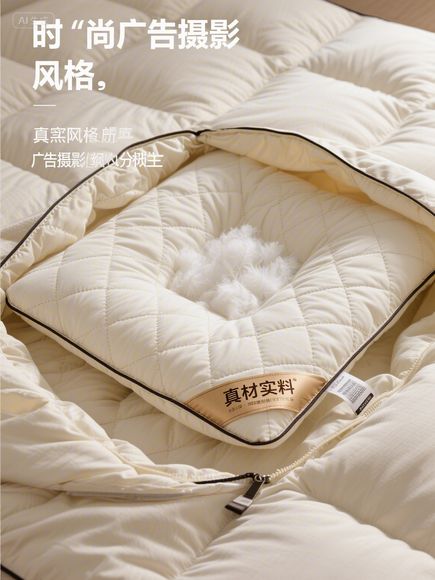

Custom Sofa Sphere Mattress Making in Shaxi,Henan Province

在河南省夏溪地区,定制沙发球形记忆棉床垫制作正在进行。

本文目录导读:

- Why Custom Sofa Cushions Matter

- Understanding Foam Types and Densities

- The Customization Process with Jia Yu Textile Factory

- Product Advantage Spotlight: Jia Yu Textile Factory

- Beyond the Cushion: Filling Options

- The Future of Custom Cushions

- Conclusion

Dear customer,

随着生活品质的提升,沙发海绵垫子已经成为家居装饰中不可或缺的一部分,我们将为您介绍涉县佳羽纺织厂专门定制的沙发海绵垫子,并详细阐述其产品优势。

产品介绍

涉县佳羽纺织厂专注于沙发海绵垫子的定制生产,其产品采用优质海绵材料,经过精心设计和工艺处理,具有以下特点:

- 高品质海绵材料:选用环保、无毒、柔软舒适的海绵,确保使用安全。

- 舒适度与耐用性兼备:根据不同用户需求和家居风格,定制海绵厚度和软硬度,确保长时间使用仍保持舒适度。

- 环保材料:采用可持续材料生产,符合环保标准,减少对环境的影响。

产品优势说明

- 高性价比:相较于市场上其他同类产品,涉县佳羽沙发海绵垫子具有更高的性价比,满足不同预算需求。

- 定制化服务:根据用户需求和家居风格,提供个性化定制服务,满足不同需求。

- 产品优势:采用先进生产工艺,确保产品柔软舒适、耐用性强;采用环保材料,符合现代家居绿色环保理念。

案例说明

佳羽纺织厂在涉县地区拥有先进的生产设备和专业的技术团队,能够根据用户需求和家居风格,提供专业的沙发海绵垫子定制服务,以下是一个案例:

某家庭在定制沙发海绵垫子时,考虑到家庭装修风格和成员喜好,选择了适合的厚度和软硬度,确保沙发既舒适又美观,经过一段时间的使用,该家庭反馈说,沙发海绵垫子不仅舒适度高,而且使用寿命长,符合预期效果。

关于佳羽纺织厂涉县定做沙发海绵垫子的用英语说明

The products from our factory in Shaxi, Henan Province are designed with high-quality foam materials that are environmentally friendly and comfortable. With customization services based on user needs and home style, these cushions offer both comfort and durability, ensuring long-lasting use. Moreover, they are made using sustainable materials, adhering to modern green environmental concepts in home decoration. 仅供参考,如需更多信息,请咨询佳羽纺织厂或访问其官方网站,祝您选购愉快!

希望以上回答对您有所帮助,如果您还有其他问题或需要更多信息,请随时告诉我。

Expanded Knowledge:

Ever wondered what makes a sofa truly comfortable? It often boils down to the cushions, and more specifically, the quality and type of foam used inside. In the heart of Xinxiang, China, a key player in this comfort industry is Jia Yu Textile Factory, specializing in custom sofa sponge cushions. If you're looking for bespoke foam solutions for your furniture, understanding the nuances of custom cushion manufacturing is key.

Let's dive in!

Why Custom Sofa Cushions Matter

Standard foam cushions often fall short. They might provide initial comfort but can lose their shape, develop lumps, or simply not meet the specific comfort needs of a particular design or user. Custom cushions, on the other hand, are tailored solutions.

- Tailored Comfort: You can specify the exact density, firmness, and even the shape of the foam to match the contours of the sofa and the desired feel for the user.

- Durability: Using higher quality, appropriately dense foam ensures the cushions maintain their shape and comfort for years, resisting body impressions.

- Design Flexibility: Custom cushions allow for unique and complex shapes that standard foam might not accommodate, enabling innovative furniture designs.

- Brand Identity: Offering cushions that are specifically designed for your sofa model can enhance the perceived quality and value of your product.

Understanding Foam Types and Densities

The world of foam is vast. Here's a quick comparison of common types used in furniture cushions:

| Foam Type | Density (LBS/FT³) | Typical Use | Characteristics |

|---|---|---|---|

| High Resilience (HR) | 0 - 3.5+ | Premium seating, office chairs | Fast recovery, durable, used in mid to high-end furniture |

| Standard Resilience (SR) | 0 - 2.5 | General upholstery, budget furniture | Good balance of comfort and cost, less durable than HR |

| Open Cell Foam | Varies | Outdoor cushions, acoustic panels | Lightweight, breathable, water-resistant |

| Memory Foam | 0 - 3.0 | Ergonomic seating, specialized support | Conforms to body shape, pressure relieving |

- Density: Measured in pounds per cubic foot (LBS/FT³). Higher density generally means better durability and support. HR foam typically starts around 3.0 LBS/FT³, while SR foam is often in the 2.0-2.5 range. Open cell foam density varies significantly based on application.

- Resilience: How quickly the foam returns to its original shape after being compressed. HR foam has high resilience, while SR foam is more moderate.

- Open Cell vs. Closed Cell: Open cell foam is softer and more conforming, great for comfort but less resistant to body oils and moisture. Closed cell foam (like HR) is denser, more resistant to compression and liquids, and often used in upholstery.

Choosing the right density depends entirely on the application. A plush sofa might use softer, lower-density foam for the top layer, while the internal structure might require higher-density support foam.

The Customization Process with Jia Yu Textile Factory

Jia Yu Textile Factory understands that one size rarely fits all, especially in furniture. Their expertise lies in transforming your specifications into tangible, high-quality cushion solutions.

Q: How does the ordering process work for custom cushions?

A: It's collaborative. You provide details about the required dimensions, desired shape (often provided via a 2D or 3D drawing), preferred foam density, and sometimes even the desired feel or specific technical requirements. Jia Yu's team then works with you to finalize the specifics and produces the cushions according to these precise standards.

Q: What quality control measures do you have in place?

A: Quality is paramount. Jia Yu employs rigorous quality control throughout the production process. This includes checking raw materials, monitoring the foam molding and cutting processes for accuracy, and conducting tests on the finished foam products to ensure they meet density, resilience, and durability standards before they leave the factory.

Product Advantage Spotlight: Jia Yu Textile Factory

Jia Yu isn't just another foam manufacturer; they bring specific strengths to the table, especially for custom sofa applications:

- Consistency and Reliability: They pride themselves on producing foam with consistent quality and performance batch after batch, ensuring your customers experience the same level of comfort and durability every time.

- Custom Shape Expertise: Complex shapes are their specialty. Whether it's intricate contours for a unique sofa design or perfectly shaped inserts for specific seating areas, Jia Yu has the technology and skill to cut and mold foam accurately.

- High-Quality Materials: They source high-grade foams, often including durable High Resilience (HR) options, ensuring longevity and comfort. They can also accommodate different types of foams based on your needs.

- Scalability: From small batch orders for unique designs to large volume production runs for furniture manufacturers, Jia Yu can scale their production to meet your business requirements.

- Competitive Pricing: By focusing on efficiency and quality, Jia Yu aims to offer competitive pricing without compromising on the quality of the foam or the precision of the custom cuts.

Case Study: The Luxury Hotel Seating Revisited

A well-known hotel chain in a major city was struggling with inconsistent comfort levels in their lobby and suite seating. Guests often complained about cushions becoming lumpy after just a few months. They needed a solution that offered uniform, high-quality support and comfort across hundreds of different sofa models.

They partnered with Jia Yu Textile Factory. Instead of using a single, standard foam density across all seats, Jia Yu worked closely with the hotel's design team. For each sofa model, they specified the exact combination of foam densities and shapes needed to achieve optimal comfort and longevity. Jia Yu provided detailed samples for testing and then implemented a rigorous QC process for every cushion produced. The result? Significantly reduced guest complaints, extended lifespan of the cushions, and a marked improvement in the perceived quality of the hotel's furniture.

Beyond the Cushion: Filling Options

While foam is king for support and comfort, the filling inside the cushion cover also plays a role in overall feel and longevity. Common fillings include:

- Foam: As discussed, provides structure and support.

- Down & Feather: Offers a soft, plush feel but can flatten quickly and require more maintenance.

- Synthetic Fiber Blends (e.g., Fiberfill, Polystyrene Beads): Often used for cost-effective solutions or for a softer, more yielding feel, but generally less supportive than foam.

Often, cushions use a combination of fillings – perhaps a high-density foam base for support and a softer foam or fiberfill top layer for comfort.

The Future of Custom Cushions

Technology is always evolving. Innovations like foam with integrated cooling properties, more sustainable and eco-friendly foam materials, and even smart foams that adapt to body temperature are on the horizon. Custom cushion manufacturing will likely continue to embrace these advancements, offering even more tailored and beneficial seating solutions.

Conclusion

Custom sofa sponge cushions are the unsung heroes of comfortable furniture. Choosing a reliable partner like Jia Yu Textile Factory in Xinxiang means tapping into expertise in customization, quality control, and material science. By understanding foam types, densities, and the importance of bespoke manufacturing, you can ensure your furniture offers the ultimate comfort and stands the test of time. Whether you're a furniture designer, manufacturer, or retailer, investing in high-quality, custom cushions is an investment in customer satisfaction and product longevity.