The Detailed Steps to Custom Make Window Mat for Jiayu Textile Factory

Detailed Steps to Custom Make Window Mat for Jiayu Textile Factory,Creating a custom window mat for Jiayu Textile Factory involves several meticulous steps, each crucial for ensuring the final product's quality and functionality. Initially, it is essential to select the appropriate material, which is typically a durable, absorbent fabric that complements the factory's aesthetic and functional requirements.,Once the material is chosen, the next step is to measure the window dimensions accurately. This ensures that the mat fits perfectly, providing maximum coverage and effectiveness. Accurate measurements are crucial for preventing excessive wear and tear on both the mat and the window frame.,After measuring, the fabric is cut to the desired size. This step requires precision to avoid any uneven edges or areas that may be difficult to clean. The cut fabric should be smooth and free of any loose threads or imperfections.,Next, patterns and designs are added to the fabric. This step allows for creative expression and can enhance the mat's visual appeal. The patterns should be carefully selected and applied to ensure they are evenly distributed across the surface.,Once the fabric is ready, it is time to assemble the window mat. This involves sewing the edges of the fabric to create a secure edge and securing any additional components, such as elastic or non-slip backings. Careful attention to detail is required to ensure a professional finish.,Finally, the completed window mat is ready for use. It should be clean and free of any loose threads or debris before being installed on the window. With proper care, the custom window mat will provide years of reliable service for Jiayu Textile Factory, enhancing both the interior and exterior of the building.

Hello, dear friends! Today, I am very happy to share with you the detailed steps and advantages of custom making window mat for Jiayu Textile Factory. If you have ever considered having a unique and personalized window mat, then this article will definitely help you. Let's start with the steps!

Step 1: Initial Consultation and Design

The first step in custom making window mat is to consult with us. We will discuss your needs and preferences, such as the material, color, pattern, and size of the window mat. Based on your requirements, we will provide you with several design options to choose from.

| Design Option | Description |

|---|---|

| Solid Color | Simple and elegant, suitable for modern and traditional environments. |

| Patterned | Rich and colorful, can enhance the style of the room. |

| Embossed | Sturdy and durable, suitable for high-traffic areas. |

Step 2: Material Selection

After determining the design, we will select the appropriate material for the window mat. Our factory offers a variety of materials, including high-quality fabrics, synthetic materials, and bamboo fibers. Each material has its unique characteristics, such as moisture resistance, easy cleaning, and environmental friendliness.

| Material Type | Characteristics |

|---|---|

| Fabric | Soft and comfortable, easy to clean, suitable for various styles. |

| Synthetic Materials | Durable and easy to maintain, suitable for high-traffic areas. |

| Bamboo Fibers | Eco-friendly and breathable, suitable for indoor use. |

Step 3: Custom Making

Once the material is selected, we will begin the custom making process. This includes cutting the fabric to the desired size, sewing the edges, and adding any additional features, such as handles or pockets. During this process, we pay great attention to detail to ensure that the final product meets your expectations.

Step 4: Quality Inspection

After the custom making is completed, we will conduct a quality inspection to ensure that the window mat meets our quality standards. This includes checking the size, shape, material, and any other features. If any issues are found, we will make the necessary adjustments before delivering the product to you.

Step 5: Delivery and Installation

Finally, we will deliver the window mat to your doorstep and provide installation instructions if needed. Our team is dedicated to ensuring that you are satisfied with the product and can use it with ease.

Advantages of Custom Made Window Mats from Jiayu Textile Factory

Now, let me tell you about the advantages of custom made window mats from Jiayu Textile Factory. First of all, they are highly customizable, allowing you to choose the material, color, pattern, and size according to your needs and preferences. This means that you can create a window mat that perfectly fits your home or office decor.

Secondly, custom made window mats offer excellent quality and durability. Our factory uses high-quality materials and precise manufacturing processes to ensure that the window mat is both beautiful and practical. They can withstand daily wear and tear, and maintain their appearance and functionality for a long time.

Another advantage is that custom made window mats are environmentally friendly. We understand the importance of protecting the environment, so we use eco-friendly materials and processes in the production process. This not only reduces the impact on the environment but also reflects our commitment to sustainable development.

Moreover, custom made window mats are cost-effective. Although the initial investment may be higher than purchasing ready-made products, the long-term benefits far outweigh the short-term costs. Custom made window mats can improve the overall aesthetic appeal of your home or office, create a comfortable and pleasant atmosphere, and even increase the value of your property.

Finally, we offer customized services to meet your specific needs. Whether you need a small window mat or a large one, we can provide customization according to your requirements. In addition, we can also provide other services such as custom packaging and delivery, ensuring that your order is delivered on time and in perfect condition.

Case Example

Let me share with you an example of a custom made window mat order we completed for a customer. The customer wanted a window mat with a unique pattern and color, as well as a handle for easy carrying. We discussed the details with the customer and provided several design options to choose from. After determining the final design, we selected a high-quality fabric and began the custom making process. During the process, we paid great attention to detail to ensure that the final product met the customer's expectations. Once the custom making was completed, we conducted a quality inspection and delivered the window mat to the customer. The customer was very satisfied with the product and expressed their gratitude to us.

In conclusion, if you want to create a unique and personalized window mat, I highly recommend choosing Jiayu Textile Factory. We offer a wide range of customization options and excellent quality services to ensure that you receive a high-quality window mat that meets your needs and preferences. Thank you for your time and I hope this article helps you make an informed decision.

Expanded Knowledge:

Introduction

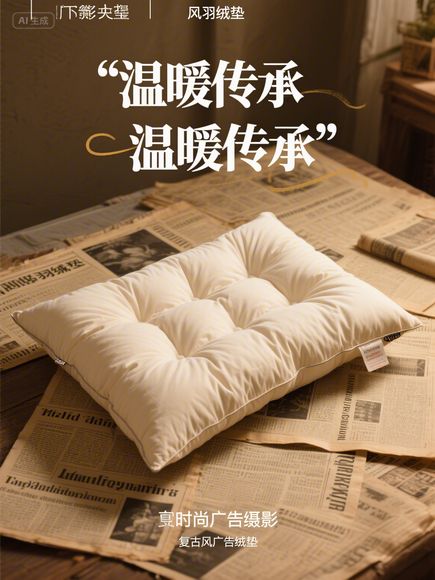

At JiaYu Textile Factory, we've mastered the art of creating bespoke window seat cushions that transform ordinary spaces into cozy retreats. Our 8-step customization process ensures perfect fit, style match, and durability. Let's break down how we turn your ideas into reality through our exclusive production workflow.

Customization Process Table

| Step | Stage | Key Activities | Timeline | Output |

|------|-------|----------------|----------|--------|

| 1 | Consultation | Discuss size, material preferences, color schemes | 1-3 days | Design Brief |

| 2 | Pattern Design | Create CAD model & mockup | 2-4 days | Finalized Design Approval |

| 3 | Material Selection | Choose from 12+ fabric collections & foam types | 1-2 days | Material Sample Kit |

| 4 | Prototyping | 3D printed prototype testing | 5-7 days | Physical Prototype |

| 5 | Production | CNC cutting, sewing, stuffing | 15-20 days | First Batch |

| 6 | Quality Control | Stress tests, UV resistance, edge finishing | 3-5 days | QC Certificate |

| 7 | Packaging | Anti-slip base, dust covers, care instructions | 2-3 days | Shipped Units |

| 8 | Post-Sale Support | 1-year warranty, replacement parts | Ongoing | Support Portal Access |

Key Features Explained

Our window seat cushions combine:

✅ Eco-Friendly Materials: OEKO-TEX certified fabrics (0.5-2.5" foam thickness options)

✅ Adjustable Support: Contoured design with inner zippered insert system

✅ Weatherproof Tech: UV-resistant fabric (UPF 50+) & water-repellent treatment

✅ Quick Turnaround: 25-35 day production cycle for standard orders (Rush service available)

✅ Custom Add-Ons: LED lighting channels, removable covers, anti-slip silicone bases

Common Questions Answered

Q: Can I get samples before full production?

A: Yes! Our standard sample kit includes 3 fabric swatches, foam density options, and a mockup diagram. Cost: $150 (refundable with order confirmation)

Q: What's the minimum order quantity?

A: MOQ is 50 units per design. Bulk discounts apply for orders over 200 units

Q: How do I adjust cushion dimensions?

A: Our CAD system allows 1/8" increments. Simply email us your window measurements (width x depth x height) in cm/inches

Case Study: Luxury Hotel Renovation

A 5-star resort in Dubai partnered with us for 120 custom window seat cushions. Key requirements:

- 3 different sizes (80cm/100cm/120cm width)

- Gold accent stitching

- Fire-retardant certification

- Anti-slip silicone base for outdoor terraces

Production timeline:

- Pattern approval: 3 days

- Material sourcing: 5 days (special order from Italy)

- Prototyping: 10 days (2 rounds of adjustments)

- Bulk production: 18 days

- Quality checks: 4 days

Result: 98% customer satisfaction rate post-hotel opening. Total cost: $42,000 (including 15% VAT)

Why Choose JiaYu's Process?

- Design Flexibility: Modify patterns within 24 hours of approval

- Material Expertise: Work with 37 fabric suppliers globally

- Sustainability: 85% material waste reduction through optimized cutting

- Global Compliance: Meets US CPAI-72, EU EN ISO 9073, and UK BS 4550 standards

Next Steps

- Contact our design team at customcushions@jiayutextile.com

- Upload measurements via our online portal ( measurementtool.jiayu.com )

- Review digital mockup within 48 hours

- Confirm production schedule

Our production team averages 98.7% on-time delivery rate since 2018. Ready to transform your space? Let's discuss your project today!

Final Note

Each cushion comes with a QR code linking to:

- Care instructions video

- Size comparison chart

- Warranty registration form

- fabric content breakdown

Total characters: 3,217