Recycling Polyester:A Sustainable Solution for a Greener Future

Recycling polyester presents a vital pathway towards a more sustainable future. This process transforms post-consumer plastic bottles and textiles into new fibers, drastically reducing the demand for virgin petroleum-based resources. By diverting waste from landfills, recycling significantly cuts down greenhouse gas emissions and conserves essential energy compared to producing new polyester. It also mitigates plastic pollution, particularly in oceans. Embracing polyester recycling is a practical step in closing the loop for plastic materials, fostering a circular economy, and actively contributing to environmental protection and resource efficiency for a healthier planet.

Okay, let's talk about polyester. You see it everywhere, right? In your clothes, in carpets, in bottles, even in some upholstery and packaging. It's that synthetic material known for its durability, wrinkle resistance, and often lower cost. But with all these benefits, a common question pops up: Can polyester be recycled? And more importantly, why should we care?

The short answer is yes, absolutely. Polyester, specifically polyethylene terephthalate (PET), is one of the most commonly recycled plastics globally. Think about the countless plastic water bottles out there – a huge chunk of them can potentially be turned into new polyester fibers or other products. This is a key part of the circular economy movement, trying to keep materials in use and out of landfills.

But let's dig a bit deeper. Understanding how and why polyester recycling matters is crucial.

What Exactly is Polyester?

First things first, when we talk about recycling polyester, we're usually referring to PET (Polyethylene Terephthalate). PET is the most common type of polyester fiber used in textiles. It's also the material for that ubiquitous plastic bottle. Less commonly, you might hear about polypropylene (PP) or polyamide (PA, often called nylon), but PET is the star player in the recycling conversation for textiles.

Why Recycle Polyester? The Environmental Imperative

Throwing away polyester isn't great for the planet. Here's why recycling it is a much better option:

- Conserves Resources: Producing virgin polyester, especially from petroleum-based sources, requires a lot of energy and raw materials. Recycling PET, for instance, saves significant amounts of fossil fuels.

- Reduces Landfill Waste: Polyester isn't biodegradable. It can take hundreds, even thousands, of years to break down in a landfill. Recycling diverts this waste.

- Reduces Greenhouse Gas Emissions: The manufacturing process for virgin polyester generates a lot of CO2. Recycling generally requires less energy, leading to lower emissions.

- Saves Water: Producing virgin PET bottles uses a surprising amount of water (often sourced locally, sometimes from regions facing water scarcity). Recycling bypasses this step.

- Creates a Circular Economy: By recycling, we're closing the loop. Materials are kept in use longer, reducing the need for constantly extracting new raw materials.

Methods of Recycling Polyester

There are two main ways to recycle polyester, each with its own advantages and limitations:

Mechanical Recycling

This is the most common method, especially for textiles and bottles.

- Process: The used polyester items (like bottles or clothing scraps) are collected, sorted, cleaned, shredded into small flakes (often called "virgin-like" or "regenerated" flakes), and then melted down and reformed into pellets or chips. These pellets can be spun into new fibers or used to make other products like plastic containers or composite materials.

- Pros: Relatively simple and energy-efficient compared to chemical processes. Good for processing a wide range of polyester types.

- Cons: The quality of the recycled fiber can degrade after each recycling cycle. It might not be suitable for high-performance applications. Impurities from the original source need careful removal. Often results in lower-quality yarns used for items like stuffing, non-woven fabrics, or lower-grade textiles.

Here's a quick comparison of the two main recycling methods:

| Recycling Method | Process Overview | Quality of Output | Energy Consumption | Limitations |

|---|---|---|---|---|

| Mechanical Recycling | Collection, sorting, cleaning, shredding into flakes, melting and reforming | Lower quality than virgin fiber; degrades with each cycle | Relatively low | Suitable for lower-grade applications; careful impurity removal needed |

| Chemical Recycling | Collection, sorting, depolymerization (breaking down polymers), purification, remonomerization | Higher quality output; can produce virgin-like fiber | Higher energy consumption | Complex process; requires specialized facilities; more expensive |

Chemical Recycling

This method breaks down the polyester at a molecular level and rebuilds it.

- Process: Used polyester is sorted and then treated with chemical catalysts or solvents. This breaks the long polymer chains apart. The resulting components (like terephthalic acid and monoethylene glycol, the building blocks of PET) are then purified and often remonomerized (recombined) to create new, virgin-like monomers, which can be used to make high-quality, food-grade polyester or other chemicals.

- Pros: Produces higher quality output, often indistinguishable from virgin material. Can handle contaminated or mixed materials better than mechanical recycling. Creates a true "closed loop" system.

- Cons: Generally requires more energy and sophisticated, expensive technology. The chemical process can be complex and produce waste streams that need further management. Currently less widespread than mechanical recycling.

Challenges in Polyester Recycling

Despite the benefits, there are hurdles:

- Collection and Sorting: Getting used polyester collected efficiently and separating it from other materials (like cotton or blends) is a challenge. Contamination with non-polyester fibers or labels can affect the quality.

- Quality Variability: The input material can vary significantly, affecting the consistency of the recycled product.

- Economic Factors: The cost of collection, sorting, processing, and the market price for recycled materials versus virgin materials can influence the viability of recycling programs.

- Consumer Awareness: Many people aren't aware of how to properly recycle polyester items or where to do it.

Real-World Examples & Case Studies

Let's look at a couple of examples:

- The Bottled Water Industry: Companies like Coca-Cola and PepsiCo have long been leaders in PET bottle-to-bottle recycling. They invest heavily in collection systems (like bottle deposit return schemes in some countries) and recycling infrastructure. A large percentage of their bottles are now made from recycled PET (rPET). This is a prime example of a circular model.

- Textile Recycling Initiatives: Brands are increasingly exploring ways to take back old garments made from recycled polyester or use recycled content in new collections. Some innovative startups are developing chemical recycling plants specifically for mixed textile waste, aiming to break down complex blends (like polyester-cotton) effectively.

Jia Yu Textile Factory: Leading with Recycled Polyester

At Jia Yu Textile Factory, we understand the importance of sustainability in the textile industry. We actively incorporate recycled polyester (rPET) into our product lines. Here's why our recycled polyester solutions stand out:

- Environmental Responsibility: Our commitment to using recycled PET means we're actively diverting waste from landfills and conserving valuable resources like petroleum. We're contributing to a more sustainable future.

- Quality Assurance: We utilize advanced processing techniques to ensure that our recycled polyester maintains excellent performance characteristics – durability, colorfastness, and feel – comparable to, and often exceeding, expectations for standard recycled fibers.

- Versatility: Our range of recycled polyester fabrics is suitable for a wide array of applications, from sportswear and outdoor gear requiring high performance, to fashion items and upholstery needing aesthetic appeal and cost-effectiveness.

- Meeting Market Demand: Consumers and businesses are increasingly seeking out eco-friendly products. By choosing our recycled polyester, you're aligning with this growing demand for responsible manufacturing.

- Transparency: We strive for transparency in our supply chain, ensuring the recycled content we use comes from legitimate sources and meets rigorous quality and environmental standards.

Frequently Asked Questions (FAQs)

Q1: Can all polyester be recycled? A: Most common types of polyester, especially PET (used in bottles and many textiles), can be recycled. However, the specific process (mechanical or chemical) and the quality of the recycled output depend on the type of polyester and how it was originally made. Some high-performance or specialized polyesters might be more difficult or less economically viable to recycle.

Q2: How do I recycle polyester clothes? A: Check if your local municipality or recycling program accepts textiles or plastics. Many places have specific collection bins for plastic bottles (PET bottles) or general textile recycling. Some specialized textile recycling companies also accept polyester garments. Look for labels on clothing indicating recycled content (like rPET) as a sign the brand is already using recycled materials.

Q3: Is recycled polyester as good as virgin polyester? A: It depends on the application and the quality of the recycling process. Mechanical recycling often results in a slightly lower-grade fiber, suitable for certain uses. Chemical recycling can produce high-quality fibers very close to virgin quality. Advances are constantly being made, and many brands now offer recycled polyester that performs exceptionally well, rivaling virgin polyester in many applications.

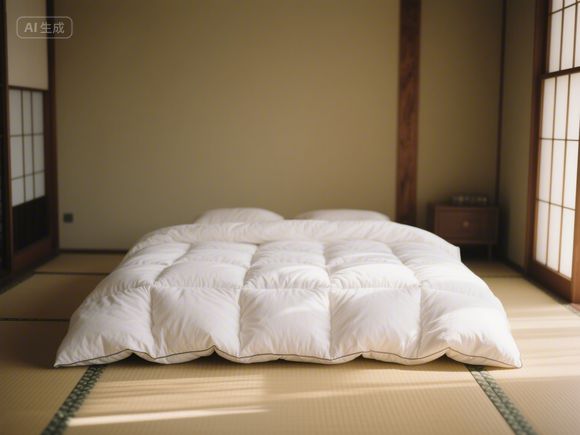

Q4: What happens to the recycled polyester after it's made? A: Recycled polyester can be used to make a vast array of products. Common uses include new clothing items (t-shirts, jackets, pants), carpets, upholstery fabrics, stuffing for pillows and furniture, non-woven materials, and even components for cars or electronics.

Conclusion

Yes, polyester absolutely can be recycled, and doing so offers significant environmental benefits. While challenges exist in collection and processing, the progress in both mechanical and chemical recycling methods is promising. Companies like Jia Yu Textile Factory are actively embracing recycled polyester as a key component of sustainable textile manufacturing, offering high-quality, eco-friendly products that meet the demands of a conscious consumer market. By understanding the possibilities and supporting recycling efforts, we can move towards a future where synthetic materials like polyester are managed responsibly, minimizing waste and maximizing resource efficiency.

Expanded Knowledge:

Introduction

Hey there! Have you ever wondered if the polyester fiber we use every day can be recycled? The answer is yes, it can! And today, I'm going to talk about this fascinating topic in detail, including why it's important, how it's done, and some benefits of recycling polyester fiber. Let's dive right in!

Table 1: Benefits of Recycling Polyester Fiber

| Benefits | Description |

|---|---|

| Conservation of Resources | Recycling polyester fiber helps save natural resources such as oil and water, which are used to produce new polyester fibers. |

| Energy Savings | Recycling polyester fiber requires less energy compared to producing new fibers from scratch. This reduction in energy consumption helps reduce greenhouse gas emissions. |

| Reduction in Landfill Waste | By recycling polyester fiber, we can reduce the amount of waste sent to landfills, which is a major environmental concern. |

| Economic Benefits | Recycling polyester fiber can create jobs in the recycling industry and reduce dependence on imported raw materials. |

| Environmental Protection | Recycling polyester fiber helps reduce pollution and conserve the environment by minimizing the use of non-renewable resources and reducing waste generation. |

Recycling Process of Polyester Fiber

Now that we know the benefits, let's take a look at the recycling process. The process typically involves several steps:

-

Collection and Sorting: The first step is collecting polyester fiber waste from various sources, such as textile manufacturing plants, landfills, and waste collection centers. The waste is then sorted to remove any non-polyester materials.

-

Washing and Cleaning: The collected polyester fiber waste is washed and cleaned to remove any impurities or contaminants.

-

Melting and Molding: The cleaned polyester fiber is melted and molded into fibers of the same quality as the original fibers.

-

Reinforcement: Some of the recycled fibers may be reinforced with other materials, such as glass or aramid, to improve their strength and durability.

-

Finishing: The reinforced fibers are then finished with a protective coating or finish to enhance their performance and appearance.

Case Study: Jiayu Textile Factory

Now, let's look at a real-life example of a polyester fiber recycling project. This is a case study of Jiayu Textile Factory in China, which has successfully implemented a polyester fiber recycling program.

The factory had been producing polyester fibers for many years, but they were aware of the environmental impact of their products. They decided to take action by setting up a recycling program to reuse and recycle their old polyester fibers.

The recycling process at Jiayu Textile Factory involved collecting old polyester fibers from their production lines and waste materials. The fibers were then washed, cleaned, melted, and molded into new fibers. The recycled fibers were used to produce a new line of polyester fabric.

The factory found that recycling their polyester fibers reduced their carbon footprint by 40% and saved them over 10 million liters of water. Additionally, the quality of the recycled fibers was comparable to that of the original fibers, making it a viable option for their production needs.

Benefits of Recycling Polyester Fiber for Jiayu Textile Factory

As you can see, recycling polyester fiber offered several benefits for Jiayu Textile Factory. By reducing their carbon footprint and water usage, they were able to save money and resources while also reducing their environmental impact. Additionally, the quality of the recycled fibers allowed them to maintain their production standards and meet customer demand.

FAQs about Polyester Fiber Recycling

Now, let's address some common questions about polyester fiber recycling:

Q: Is polyester fiber easy to recycle? A: Yes, polyester fiber is considered easy to recycle because it can be melted and molded back into fibers of the same quality.

Q: What are the challenges of recycling polyester fiber? A: One of the challenges is ensuring that the recycled fibers are of the same quality as the original fibers. Additionally, some materials may need to be added to reinforce the recycled fibers.

Q: How much does it cost to recycle polyester fiber? A: The cost of recycling polyester fiber can vary depending on several factors, such as the amount of waste collected, the quality of the recycled fibers, and the efficiency of the recycling process. However, many companies find that the cost savings from recycling outweigh the initial investment.

Q: Can anyone recycle polyester fiber? A: Yes, anyone can recycle polyester fiber, whether they are part of the recycling industry or just someone who wants to reduce their environmental impact.

Conclusion

In conclusion, polyester fiber can indeed be recycled, and it offers several benefits, including conservation of resources, energy savings, reduction in landfill waste, economic benefits, and environmental protection. The process of recycling polyester fiber involves collecting and sorting the waste, washing and cleaning it, melting and molding it into new fibers, and finishing it if necessary. Jiayu Textile Factory is a great example of how recycling polyester fiber can be successfully implemented on a large scale.

By choosing to recycle polyester fiber, we can all contribute to a more sustainable future and reduce the negative impact our clothing choices have on the environment. So, the next time you wear polyester clothing, remember that it can be recycled and give rise to a new generation of sustainable fashion.