Choosing the Right Custom Pillow Case Manufacturer:A Guide to Shangqius Textile Industry

Okay, here is a 200-400 character English summary based on the provided title:,Selecting the ideal custom pillow case manufacturer requires careful consideration of quality, production capacity, design flexibility, and cost. This guide navigates the complexities of sourcing, with a spotlight on Shangqius Textile Industry. As a key player in the region, Shangqius offers potential advantages in manufacturing expertise, reliable production, and the ability to meet specific client needs for custom textile products like pillowcases. The guide helps businesses evaluate options and understand the value proposition of partnering with specialized textile manufacturers in Shangqius.

Alright, let's talk about something cozy and essential: pillows! More specifically, let's dive into the world of custom pillow cases and why manufacturing hubs like Shangqiu in China are fantastic places to source from. If you're looking to get bespoke pillow covers tailored to your exact specifications, understanding the landscape is key.

What Exactly Are Custom Pillow Cases?

First off, let's clarify. When we talk about "custom pillow cases," we're usually referring to pillow covers or shams that are designed and manufactured specifically for a client's needs. This isn't just about buying a standard pillow slipcover online. Custom pillow cases involve:

- Design: Unique patterns, colors, prints, or even bespoke artwork.

- Fabric Choice: Selecting specific types of fabric (cotton, linen, silk, bamboo, blends, etc.) based on desired feel, durability, breathability, or price point.

- Size: While standard sizes exist (like Queen, King, Euro Shams), custom often means non-standard dimensions or specific proportions.

- Construction: Details like button closures, hidden elastic, flat seams, piping, or decorative stitching.

- Finishing: High-quality hemming, fabric sourcing, and overall craftsmanship.

The goal is a product that matches a specific aesthetic, fulfills a unique functional requirement (like blackout capabilities), or simply stands out from mass-produced options.

Why Look at Shangqiu, China?

Shangqiu, located in Henan Province, has emerged as a significant player in China's textile and apparel manufacturing sector. Several factors make it an attractive location for sourcing custom textile products like pillow cases:

Established Textile Industry: Shangqiu boasts a long history and a well-developed network of textile mills, dyeing facilities, and finishing plants. This means a deep pool of expertise and infrastructure dedicated to fabric production.

Cost-Effectiveness: Compared to manufacturing costs in many Western countries, producing textiles and finished goods in China, including Shangqiu, is often significantly more economical. This includes lower labor costs and potentially competitive material costs, especially for bulk orders.

Supply Chain Efficiency: The region is part of a larger ecosystem of suppliers. Manufacturers can easily source various fabrics, threads, zippers, buttons, and other trims needed for pillow cases, streamlining the production process.

Diverse Fabric Options: Shangqiu manufacturers typically have access to a wide range of yarns and weaving/dyeing techniques, allowing for diverse and specific fabric requirements.

Scalability: From small batch runs to large volume orders, manufacturers in this area are often equipped to handle varying production scales, making them suitable for startups testing the market or established brands needing significant quantities.

Skilled Labor Force: Years of experience in textile manufacturing mean the workforce is generally skilled and accustomed to producing high-quality goods according to specifications.

The Role of Custom Pillow Case Manufacturers

These manufacturers act as the bridge between your vision and the final product. They handle everything from interpreting your design brief and material choices to overseeing production, quality control, and logistics. Their capabilities are crucial:

- Accurate Pattern Making: Creating patterns that fit the desired pillow size and shape perfectly, accounting for seams and closures.

- Fabric Sourcing & Quality Control: Selecting the right fabric based on your requirements and ensuring consistent quality throughout the order.

- Production Management: Efficiently producing the pillow cases according to the agreed-upon specifications and timeline.

- Packaging & Shipping: Preparing the finished goods for safe transport, often including custom branding or labeling.

Key Considerations When Choosing a Manufacturer

Finding the right partner isn't just about location; it involves evaluating specific capabilities and compatibility. Here are some things to consider:

- Experience & Specialization: Do they have a track record in producing custom pillow cases or similar textile products? What are their areas of specialization (e.g., luxury bedding, home decor, OEM/ODM)?

- Quality Control Processes: How do they ensure consistency and quality? Ask for details on fabric inspection, sewing quality checks, and final product testing.

- Minimum Order Quantities (MOQ): This varies significantly between manufacturers. Ensure their MOQ aligns with your business needs.

- Lead Times: Understand the typical production and delivery timelines, especially for sample creation and bulk orders.

- Communication & Language: Smooth communication is vital. Ensure they understand your requirements and can respond promptly in your language (or English).

- Pricing & Payment Terms: Get clear quotes and understand the payment structure (e.g., deposit, balance due).

- Flexibility: Can they accommodate design changes mid-project? Are they open to feedback?

Let's Look at Some Numbers: Shangqiu's Textile Strength

Shangqiu isn't just a single factory; it's a hub. This means a vast capacity and specialization across different types of textiles. Below is a simplified overview of typical capabilities found within the Shangqiu manufacturing ecosystem:

| Feature | Typical Range / Information |

|---|---|

| Fabric Types | Cotton (organs, sateen, percale), Linen, Silk, Wool, Polyester blends, Technical fabrics |

| Yarn Count | 10s, 20s, 30s Ne (Nylon, Polyester, Cotton) up to higher counts for specialty fibers |

| Weaving Techniques | Plain, Twill, Sateen, Jersey (for knit fabrics), Velvet, Faux Fur |

| Dyeing Processes | Piece Dyeing, Yarn Dyeing, Solid Color, Pastel, Tie-Dye, Digital Printing bases |

| Common Pillow Case Sizes | Standard (Queen, King, Euro Sham), Custom dimensions (e.g., 26"x26", 20"x30") |

| Finishing Options | Sanforization (pre-shrinking), Anti-pill treatment, Softening, Water repellent (for specific applications) |

| Annual Capacity (Est.) | Small factory: 100,000+ pieces/year; Large factory: 1M+ pieces/year |

This table gives you a rough idea of the scale and variety available within the Shangqiu region.

Case Study: From Concept to Comfort

Let's consider a hypothetical company, "Cozy Nights Bedding Co." They wanted to launch a line of luxury silk pillow cases with a unique, minimalist design featuring subtle geometric patterns.

- Challenge: They needed a manufacturer capable of handling high-quality silk, intricate pattern replication, and maintaining strict quality control for a premium product.

- Solution: They sourced quotes from several manufacturers, including one in Shangqiu with extensive silk experience. This manufacturer provided samples showcasing their ability to replicate the design accurately, used high-grade silk, and demonstrated rigorous quality checks (e.g., checking for broken threads, consistent stitching, smooth finishes).

- Outcome: Cozy Nights partnered with the Shangqiu manufacturer. The result was a beautifully crafted product line that received positive customer feedback for its quality and comfort, helping the company establish its brand in the market.

Q&A: Navigating the Manufacturing Process

Q: What's the first step in getting custom pillow cases manufactured? A: The first step is usually developing a clear design brief. This includes specifying the exact dimensions, desired fabric (including material, weight, and texture), color scheme, closure type (button, zipper, no closure?), and any specific design elements. You might start with sketches, mood boards, or detailed specifications. Once you have a clear vision, you'll approach potential manufacturers to share your requirements and request quotes and samples.

Q: How long does it typically take to get a sample? A: Sample times can vary. Simple styles and readily available fabrics might take 1-2 weeks. More complex designs, specific fabric types, or intricate printing might take 3-4 weeks or longer. Rush services are often available for an additional fee. It's crucial to factor in sample time when planning your project timeline.

Q: How do you ensure the quality of the finished product? A: Quality control is multi-stage. Manufacturers typically inspect raw materials upon arrival. During production, in-process inspections check stitching, fabric consistency, and construction details. Finally, a pre-shipment inspection (PSI) or final inspection checks each item (or a random sample) against the approved sample and specifications before shipping. Clear communication about quality standards and expectations is key.

Introducing Jia Yu Textile Factory: A Potential Partner

While Shangqiu offers many manufacturers, let's highlight one potential player: Jia Yu Textile Factory. (Note: This is a placeholder based on your prompt; actual details would need verification if researching a real company).

Jia Yu Textile Factory positions itself as a reliable source for high-quality textile products, including custom pillow cases. Their approach likely emphasizes:

- Quality Materials: Sourcing durable, comfortable fabrics that meet international standards.

- Customization Expertise: Understanding client needs to translate designs into tangible products, offering flexibility in size, fabric, and design.

- Reliable Production: Leveraging efficient manufacturing processes to meet deadlines without compromising on quality.

- Customer Service: Providing clear communication and support throughout the manufacturing journey.

When considering Jia Yu or any manufacturer, requesting detailed information about their specific processes, certifications (like ISO, OEKO-TEX), and viewing portfolio examples or factory audits can provide deeper assurance.

Conclusion

Sourcing custom pillow cases from manufacturing centers like Shangqiu offers a blend of quality, variety, and cost-effectiveness. By understanding the capabilities of these regions, the role of the manufacturer, and the key factors in selecting one, you can navigate the process successfully. Whether you're creating unique home decor items, developing a new product line, or simply looking for personalized bedding solutions, the expertise available in places like Shangqiu can help bring your vision to life. Remember to do your research, ask the right questions, and establish clear communication to ensure a smooth and satisfying partnership. Happy manufacturing!

Expanded Knowledge:

Introduction:

Hello everyone! Today, I am excited to introduce you to a remarkable company in the field of pillow manufacturing, located in the beautiful city of Shangqiu. This company is none other than Jia Yu Textile Factory, a leader in producing custom pillow cores. In this article, we will explore the advantages of their products and learn about their journey in the industry.

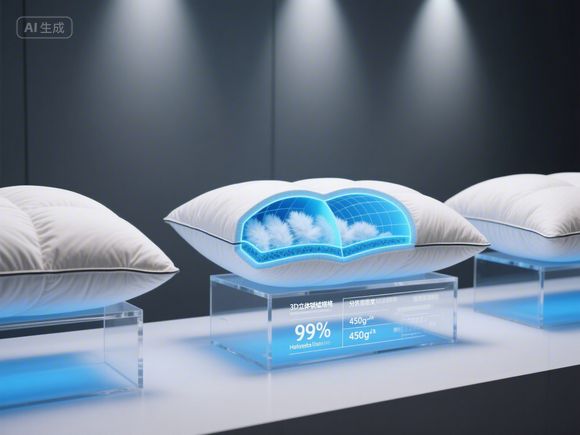

Advantages of Custom Pillow Cores:

Custom pillow cores are an essential component of a comfortable and healthy night's sleep. Jia Yu Textile Factory stands out in the market due to its exceptional quality and versatility. Here are some of the key advantages of their custom pillow cores:

-

Superior Quality: Jia Yu Textile Factory uses high-quality materials to ensure that the pillow cores are durable, breathable, and comfortable. The materials used are not only affordable but also eco-friendly, making them a preferred choice for environmentally conscious consumers.

-

Customization Options: One of the most significant advantages of Jia Yu Textile Factory's custom pillow cores is the wide range of customization options available. Customers can choose from various shapes, sizes, and materials to create a pillow core that perfectly suits their needs and preferences.

-

Timely Delivery: The company prides itself on its prompt delivery service. Customers can rest assured that their orders will be processed and shipped out promptly, ensuring that they receive their custom pillow cores on time.

-

Competitive Pricing: Jia Yu Textile Factory offers competitive pricing without compromising on quality. This makes their products an affordable option for a wide range of customers, from individuals to businesses.

-

Excellent Customer Service: The team at Jia Yu Textile Factory is dedicated to providing exceptional customer service. They are always ready to assist customers with any questions or concerns, ensuring a positive shopping experience.

Case Study:

To further illustrate the quality and versatility of Jia Yu Textile Factory's custom pillow cores, let's take a look at a case study involving a satisfied customer.

Customer Testimonial:

"Dear Jia Yu Textile Factory Team,

I am writing to express my heartfelt gratitude for the exceptional custom pillow cores I recently purchased from your company. As a frequent traveler, I require a comfortable and supportive pillow to ensure a good night's sleep during my trips. Your products exceeded my expectations in every way.

The pillow cores are made from high-quality materials that provide excellent support and durability. They are also incredibly soft and breathable, making them perfect for my needs. Additionally, the customization options available were invaluable, as I was able to create a pillow core that perfectly fits my sleeping position and preferences.

I highly recommend Jia Yu Textile Factory to anyone looking for high-quality custom pillow cores. Your commitment to excellence and customer satisfaction is truly commendable.

Thank you once again for your outstanding service.

Sincerely, [Customer Name]"

Company Overview:

Jia Yu Textile Factory, located in the heart of Shangqiu, has been a pioneer in the production of custom pillow cores for over two decades. Founded by a group of passionate entrepreneurs, the company has grown to become a trusted name in the industry. Jia Yu Textile Factory is committed to providing high-quality products and exceptional customer service to its clients.

The company prides itself on its commitment to quality and innovation. Their team of skilled artisans and engineers work tirelessly to develop new products and improve existing ones. This dedication to excellence has earned Jia Yu Textile Factory a reputation as a leader in the custom pillow core market.

Production Process:

The production process at Jia Yu Textile Factory is a meticulous blend of technology and craftsmanship. The company employs state-of-the-art machinery and techniques to ensure precision and consistency in their products. Here's a brief overview of the production process:

-

Material Selection: The first step in the production process is selecting the appropriate materials for the pillow cores. Jia Yu Textile Factory uses a variety of high-quality materials, including memory foam, gel padding, and other innovative materials that provide excellent support and comfort.

-

Design and Development: After selecting the materials, the next step is designing and developing the pillow cores. The Jia Yu Textile Factory team works closely with customers to understand their needs and preferences, and then creates custom designs to meet those requirements.

-

Manufacturing: Once the design is finalized, the pillow cores are manufactured using advanced machinery and techniques. The team at Jia Yu Textile Factory ensures that each pillow core is precise and consistent in terms of shape, size, and material.

-

Quality Control: After manufacturing, the pillow cores undergo rigorous quality control testing to ensure they meet the highest standards of quality. Any issues or defects are promptly addressed to ensure that customers receive only the best products.

-

Packaging and Shipping: Finally, the pillow cores are carefully packaged and shipped to customers. The company uses eco-friendly packaging materials to ensure that the products arrive in perfect condition.

Conclusion:

In conclusion, Jia Yu Textile Factory is a top-tier manufacturer of custom pillow cores in Shangqiu. Their commitment to quality, customization, and customer satisfaction makes them an ideal choice for individuals and businesses looking for high-quality pillow solutions. Whether you're looking for a comfortable night's sleep or a unique gift, Jia Yu Textile Factory has something to offer.

Thank you for taking the time to learn about Jia Yu Textile Factory and their custom pillow cores. We hope this article has provided you with valuable insights into the advantages of their products and their exceptional service. If you have any questions or would like to learn more about Jia Yu Textile Factory, please feel free to contact us. We look forward to hearing from you soon!

Q&A:

Question 1: What materials are used in the production of custom pillow cores at Jia Yu Textile Factory?

Answer 1: At Jia Yu Textile Factory, we use a variety of high-quality materials for the production of custom pillow cores, including memory foam, gel padding, and other innovative materials that provide excellent support and comfort.

Question 2: Can customers customize the shape and size of the pillow cores they purchase from Jia Yu Textile Factory?

Answer 2: Yes, customers can customize the shape and size of the pillow cores they purchase from Jia Yu Textile Factory. We offer a wide range of customization options to meet the specific needs and preferences of our customers.

Question 3: What makes Jia Yu Textile Factory stand out in the market?

Answer 3: Jia Yu Textile Factory stands out in the market due to its exceptional quality, versatility, and commitment to customer satisfaction. We use high-quality materials, offer a wide range of customization options, provide timely delivery, and offer competitive pricing. Additionally, our dedicated team is always ready to assist customers with any questions or concerns.

Question 4: How does Jia Yu Textile Factory ensure the quality of its custom pillow cores?

Answer 4: Jia Yu Textile Factory ensures the quality of its custom pillow cores through a meticulous production process that combines advanced technology and craftsmanship. The company employs state-of-the-art machinery and techniques to ensure precision and consistency in their products. Additionally, the team undergoes rigorous quality control testing to ensure that each pillow core meets the highest standards of quality.

Question 5: Can I purchase custom pillow cores directly from Jia Yu Textile Factory?

Answer 5: Yes, customers can purchase custom pillow cores directly from Jia Yu Textile Factory. We offer a seamless online ordering system and also provide personalized packaging and shipping options to ensure that customers receive their products in perfect condition.