Custom U-Shaped Latex Pillow Molds for Meizhou:Crafting Comfort and Support

Okay, here is a summary based on the provided title:,highlights the availability of custom U-Shaped Latex Pillow Molds specifically for Meizhou. These molds are designed to craft personalized pillows, emphasizing the key benefits of latex: comfort and support. The focus on "custom" suggests tailored shapes or sizes, while "U-Shaped" indicates a common ergonomic design. This service likely aims to provide Meizhou residents and potentially businesses with the means to create high-quality, comfortable latex pillows suited to their specific needs, leveraging local production or customization capabilities.

本文目录导读:

- Why Custom U-Shaped Latex Pillow Molds Matter

- Understanding the Basics: What Makes a U-Shaped Latex Pillow Mold?

- The Advantages of Partnering with a Specialist: Jia Yu Textile Factory

- Case Study: From Concept to Comfort with a Custom U-Shape Pillow

- Frequently Asked Questions (FAQ)

- Conclusion

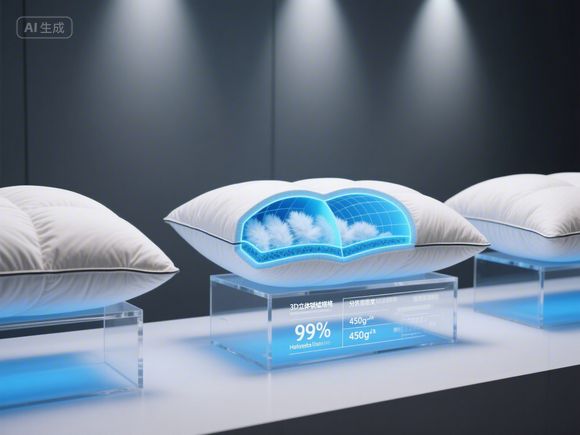

Alright, let's talk about something pretty important for folks in the bedding industry, especially those looking to produce high-quality latex pillows. We're diving deep into custom U-shaped latex pillow molds. Now, if you're thinking about manufacturing latex pillows, especially those ergonomic U-shape designs that many people swear by for better sleep and neck support, then having the right, custom molds is absolutely key. It's not just about making a pillow; it's about creating a product that fits, feels good, and lasts.

Why Custom U-Shaped Latex Pillow Molds Matter

First off, let's get one thing straight: off-the-shelf molds just won't cut it if you want a unique, ergonomic U-shape pillow. Everyone's head and neck are different, right? So, a one-size-fits-all mold won't give you the precision you need. Custom molds allow manufacturers to:

- Design the Perfect Shape: Tailor the U-shape, the contours, the height, everything to provide optimal support for the intended market segment – side sleepers, back sleepers, people with specific neck conditions, etc.

- Ensure Consistency: Once you've got a perfect mold, every single pillow produced using that mold will be an exact replica. No more guesswork in terms of shape and support.

- Optimize Latex Usage: Well-designed molds help in using the right amount of latex, reducing waste and keeping production costs down.

- Meet Brand Standards: Your pillow needs to look and feel like your brand. Custom molds ensure that the final product matches your design vision.

So, whether you're a small startup looking to make your mark or an established company wanting to innovate your product line, investing in custom U-shaped latex pillow molds is a smart move.

Understanding the Basics: What Makes a U-Shaped Latex Pillow Mold?

Okay, let's break down what goes into making these molds. Essentially, a U-shaped latex pillow mold is a negative impression – usually made from durable materials like steel or sometimes aluminum for certain applications – that dictates the final shape of the latex pillow. The mold has to be precisely engineered to create the characteristic U-shape that cradles the neck.

Key Considerations for Mold Design

- Shape Profile: This is the core. The depth, width, and curve of the U need to be carefully designed. Are the sides vertical or sloped? Is the back section wider or narrower? All these factors affect comfort and support.

- Material: The mold material needs to be strong enough to withstand the pressure of liquid latex during the pouring and curing process. Steel is common for its durability, but aluminum molds might be used for shorter runs or specific designs due to faster cooling times.

- Surface Finish: A smooth mold surface will yield a smooth pillow surface, which is important for feel and aesthetics. Rougher surfaces might be okay for certain textured latex finishes, but generally, smooth is better.

- Cavity and Core Design: Depending on the complexity, the mold might have multiple parts (cavities and cores) to form different sections of the U-shape, especially if vents or channels are needed for the latex to flow properly.

Here's a quick comparison of common mold materials and their characteristics:

| Mold Material | Pros | Cons | Typical Use |

|---|---|---|---|

| Steel | • Exceptional durability • Long lifespan (10+ years) • Consistent quality |

• Higher initial cost • Longer setup time • Heavier |

High-volume production runs |

| Aluminum | • Faster cooling cycle • Lower initial cost • Relatively lightweight |

• Less durable than steel • Shorter lifespan (fewer years) • Potential for warping |

Short-to-medium production runs |

| Plastic (Prototype) | • Lowest initial cost • Simplest design options • Fastest production |

• Very limited lifespan • Not suitable for production • Lower heat resistance |

Single prototype testing |

The Advantages of Partnering with a Specialist: Jia Yu Textile Factory

Now, if you're in the Meizhou area or looking for a reliable partner for custom latex pillow mold manufacturing, companies like Jia Yu Textile Factory come into play. They specialize in this kind of precision tooling. Here’s why working with a specialist like them can be advantageous:

- Expertise in Latex Molding: They understand the specific requirements of working with latex – the viscosity, the curing process, the pressure involved. This means they can design molds that not only look right but perform flawlessly during production.

- Customization Focus: They listen to your needs. Whether you need a simple U-shape or a complex ergonomic design, they can work with you to translate your vision into a functional mold.

- Quality Materials and Craftsmanship: Using high-grade materials ensures the mold lasts. Poorly made molds lead to inconsistent pillows, wasted material, and frustrated customers. Jia Yu likely uses robust materials to guarantee longevity.

- Technical Support: Manufacturing isn't just about the mold; it's about the whole process. A good factory will offer support, troubleshooting, and guidance on mold maintenance and production best practices.

- Supply Chain Integration: Especially for factories in manufacturing hubs like Meizhou, they might have established relationships with reliable latex suppliers, ensuring a steady and quality source of raw material.

Product Advantage Spotlight: Jia Yu Textile Factory

When you choose Jia Yu Textile Factory for your U-shaped latex pillow molds, you're not just getting a tool; you're investing in a solution designed for efficiency and quality. Their molds are engineered to:

- Maximize Yield: Minimize the chance of rejects due to shape imperfections or inconsistencies.

- Optimize Production Speed: Well-designed molds allow for efficient filling and curing cycles.

- Handle High Volumes: Built to last through thousands of production cycles without significant wear.

- Ensure Comfort and Support: The precision of the mold guarantees that every pillow meets the ergonomic specifications, providing consistent comfort and support.

Case Study: From Concept to Comfort with a Custom U-Shape Pillow

Let's paint a picture. Imagine "SleepWell Co." – a company based in Shenzhen specializing in premium sleep products. They wanted to launch a line of ergonomic cervical pillows specifically designed for office workers suffering from neck strain. The key differentiator was a unique, deep U-shape with specific contouring for the cervical curve.

They needed a mold that could produce this exact shape consistently. They explored options but found that standard molds couldn't achieve the required precision and support profile. They decided to partner with Jia Yu Textile Factory.

Working closely with Jia Yu's design team, SleepWell provided detailed specifications and even 3D models of their desired pillow shape. Jia Yu used high-grade steel to fabricate the mold, paying special attention to the core features that would define the U-shape and the supportive contours.

The result? SleepWell launched their new line of cervical pillows. Customer feedback was overwhelmingly positive. The pillows provided exactly the targeted support, were comfortable for long periods, and maintained their shape remarkably well. The consistent quality boosted SleepWell's brand reputation, leading to increased sales and repeat orders. The custom mold from Jia Yu was instrumental in their success story.

Frequently Asked Questions (FAQ)

Q1: How long does it take to create a custom U-shaped latex pillow mold? A: The timeline varies significantly based on the complexity of the design, the mold material chosen (steel takes longer than aluminum), and the level of detail required. Simple designs might take 3-6 weeks, while more complex ergonomic shapes could take 8-12 weeks or even longer.

Q2: What is the typical lifespan of a custom latex pillow mold? A: This depends heavily on usage (cycles per day), the hardness of the latex used, and maintenance. A well-maintained steel mold used in a controlled production environment can last anywhere from 5,000 to 50,000+ cycles, potentially many years. Aluminum molds have a shorter lifespan, often in the tens of thousands of cycles.

Q3: Can Jia Yu Textile Factory help with mold design if I don't have detailed specifications? A: Absolutely. Many mold manufacturing companies, including specialists like Jia Yu, offer design consultation services. They can work with you, understanding your comfort goals, target customer, and any specific requirements, to help conceptualize and refine the design before manufacturing the mold.

Q4: What file formats are needed for mold design? A: Typically, manufacturers require 3D CAD files. Common formats include STEP (.stp), IGES (.iges), and Parasolid (.x_t). It's best to confirm the specific requirements with the mold manufacturer like Jia Yu.

Q5: What is the minimum order quantity for pillows once the mold is made? A: This varies by the mold manufacturer and the specific terms of the agreement. Some manufacturers might require a certain number of pillows (a minimum order quantity) to cover the mold tooling costs. Discuss this clearly with Jia Yu before finalizing the mold order.

Conclusion

Custom U-shaped latex pillow molds are the foundation of producing high-quality, ergonomically designed pillows. They allow for precision, consistency, and the ability to meet specific market needs. Partnering with a specialist manufacturer like Jia Yu Textile Factory in Meizhou offers access to expertise, quality materials, and support crucial for successful pillow production. By investing in well-designed, durable molds, companies can enhance product quality, improve customer satisfaction, and build a strong reputation in the competitive bedding market. So, if you're ready to take your latex pillow production to the next level, start by exploring the possibilities of custom U-shaped latex pillow molds.

Expanded Knowledge:

梅州u型护颈乳胶枕头模具定制

产品优势说明

-

材料优势:

- 优质乳胶材质:采用天然乳胶,无毒、环保,具有优良的弹性和透气性。

- 高温高压成型工艺:模具设计科学,采用高温高压成型技术,确保枕头形状精确、耐用。

- 模具定制服务:根据客户需求进行个性化设计,满足不同颈部的支撑需求。

-

功能优势:

- 护颈设计:独特的u型设计,能有效支撑颈部,缓解颈椎压力。

- 舒适度优化:根据人体工学原理,枕头表面采用柔软材料,提供舒适的睡眠体验。

- 环保材料:符合国家环保标准,无化学残留,对人体无害。

案例说明

佳羽纺织厂在梅州地区为众多客户提供了u型护颈乳胶枕头模具的定制服务,该厂具有丰富的经验和专业的技术团队,能够根据客户需求进行精确的模具设计和生产。

问答环节

Q1:这款模具适用于哪些类型的枕头? A1:这款模具适用于各种类型的枕头,包括但不限于乳胶枕、记忆枕等。

Q2:这款模具的生产周期是多久? A2:模具的生产周期根据订单数量和交货时间而定,通常需要一定的时间来完成生产。

英文版介绍(表格形式)

产品优势介绍

| 产品特点 | 详细说明 | 优势说明 |

|---|---|---|

| 材料 | 采用优质乳胶材质,无毒环保 | 采用天然乳胶,优良的弹性和透气性 |

| 成型工艺 | 高温高压成型工艺 | 采用科学的高温高压成型技术,确保枕头形状精确、耐用 |

| 定制服务 | 根据客户需求进行个性化设计 | 提供定制服务,满足不同颈部的支撑需求 |

| 功能特点 | 独特的u型设计,护颈效果好 | 有效支撑颈部,缓解颈椎压力 |

| 舒适度优化 | 采用柔软材料,提供舒适的睡眠体验 | 根据人体工学原理,提供舒适的睡眠体验 |

| 环境友好性 | 符合国家环保标准,无化学残留,对人体无害 | 无化学残留,符合国家环保标准 |

结束语

梅州u型护颈乳胶枕头模具定做服务充分体现了佳羽纺织厂的专业技术和优质服务,如果您需要更多信息或有任何疑问,请随时联系我们。