Finding the Right Fit:Understanding Custom Neck Pillow Mold Costs

Okay, here is a summary based on the provided title and topic:,Finding the right custom neck pillow mold involves navigating significant costs. The price isn't fixed; it varies dramatically based on the mold's complexity, the chosen materials, and the production volume. Simple molds are less expensive, but intricate designs offer superior comfort and support at a higher initial investment. Material choices for the mold itself also impact the cost. Businesses must carefully weigh these upfront expenses against the benefits of producing high-quality, tailored neck pillows that meet specific ergonomic needs and customer preferences, ultimately aiming for a cost-effective manufacturing solution.

Okay, here is the English content as requested.

So, you're thinking about creating your own line of neck pillows, or maybe you just need a specific shape for a unique product? That's where a custom neck pillow mold comes in. But before you dive into the exciting part of designing your perfect pillow, there's an important question: How much does it cost to get a custom neck pillow mold made?

The answer isn't simple, because the cost can vary wildly depending on several factors. Think of it like getting a custom-made suit versus buying an off-the-rack one. The level of customization, the complexity, the materials, and the quantity you need all play a huge role in the final price tag. Let's break it down together.

What Exactly is a Custom Neck Pillow Mold?

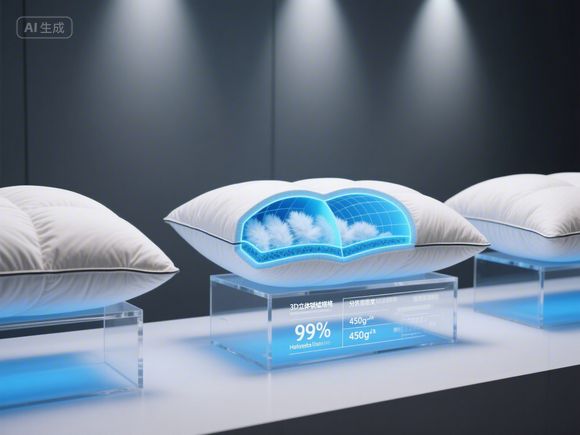

First off, let's clarify what we mean by a "mold." In this context, it's essentially a negative shape – usually made from durable plastic or silicone – that forms the cavity for your neck pillow. When you pour your chosen filling (like memory foam, gel, or microbeads) into this mold, it solidifies into the exact shape you designed. These molds are crucial for ensuring consistency in production if you're making multiple pillows, or for creating a unique, one-of-a-kind design.

Factors Influencing the Cost

Okay, so why the wide price range? Let's look at the key factors that determine how much a custom neck pillow mold will cost:

- Complexity of the Design: This is often the biggest factor. Simple, smooth shapes with straight edges and uniform thickness are much cheaper to mold than intricate designs with curves, grooves, detailed patterns, or undercuts (features that make it hard to remove the pillow from the mold). Think of a basic U-shape versus a pillow with built-in cervical support channels or a complex animal silhouette.

- Material of the Mold: The material used for the mold itself affects both the cost and its longevity. Silicone molds are popular because they are flexible, durable, easy to clean, and can release the filled product relatively easily. Injection-molded plastic molds might be cheaper for high-volume production but could be less flexible or more prone to wear. There are also more specialized materials for industrial applications.

- Size and Dimensions: Larger molds require more material and can be more complex to manufacture, driving up the cost. The thickness of the wall of the mold also matters; thicker walls are stronger but more expensive.

- Volume of Production: If you plan to make just a few prototypes, the mold cost might be a one-time investment. However, if you need to produce thousands of pillows, the cost per mold is significantly reduced because the tooling cost is spread over many units. Manufacturers often offer tiered pricing based on minimum order quantities (MOQ).

- Manufacturer/Foundry: The company you choose to fabricate the mold will have different pricing structures, overhead costs, and levels of expertise. Some specialize in small, intricate molds, while others focus on large-scale production tooling. Jia Yu Textile Factory, for instance, brings specific expertise in textile-related mold manufacturing, potentially offering advantages in certain applications.

- Surface Finish Requirements: Do you need the inside surface of the mold to be extremely smooth for a polished final product? Or does a slightly rougher finish suffice? A smoother finish often requires more polishing steps and can increase the mold's cost.

- Lead Time: Rush orders or very complex designs might require expedited manufacturing, which can add to the cost.

Getting a Custom Quote: It's Essential!

Because the cost depends so heavily on these variables, the best way to get an accurate price is to request a quote from a mold manufacturer. Don't just ask for a ballpark figure; provide as much detail as possible about your desired pillow shape, size, material preferences, and estimated production volume. This helps the manufacturer give you a realistic quote.

Estimated Price Ranges (Very Approximate)

Keep in mind these are rough estimates and can vary significantly:

- Simple Prototype Mold (e.g., basic U-shape, small quantity): $50 - $500 USD. This is often a lower-cost, perhaps silicone-based mold made for a few trials.

- Standard Production Mold (e.g., moderate complexity, smooth finish, MOQ of 1000 units): $500 - $5,000+ USD. This is a common range for many businesses. The price per unit is lower here due to the higher volume assumption.

- Complex Industrial Mold (e.g., intricate design, high volume, specialized materials): $10,000 - $50,000+ USD or more. High-end, durable molds for mass production fall into this category.

Table: Approximate Custom Mold Cost Factors (Illustrative Only)

| Factor | Low Impact/Effect | Low Cost Range | High Cost Range | Very High Cost Range |

|---|---|---|---|---|

| Design Complexity | Simple, Smooth | ✓ | ||

| Complex, Detailed | ✓ | ✓ | ||

| Mold Material | Basic Plastic | ✓ | ||

| Silicone | ✓ | |||

| Specialized | ✓ | |||

| Size (Linear Dimensions) | Small | ✓ | ✓ | |

| Large | ✓ | ✓ | ||

| Volume (Estimated Units) | Few (Prototypes) | ✓ | ✓ | |

| Medium | ✓ | |||

| High | ✓ | |||

| Lead Time | Standard | ✓ | ✓ | |

| Expedited | ✓ |

Frequently Asked Questions (FAQ)

Q1: What's the minimum order quantity for a custom mold? A: This varies greatly by manufacturer and mold complexity. Some companies might allow you to start production with just a few pillows using a prototype mold, while others require a higher MOQ for standard production molds. Be sure to ask the manufacturer about their minimums.

Q2: How long does it take to get a custom mold made? A: Again, this depends heavily on complexity and volume. A simple prototype might take a week or two. A standard production mold could take several weeks to a few months. Rush services might be available for an additional fee.

Q3: What if I want to change the design later? A: Design changes after the mold is manufactured can be costly and time-consuming. It's crucial to finalize your design before committing to mold production. Discuss potential modification costs with your manufacturer upfront.

Case Study: Finding the Right Partner

Let's consider a hypothetical company, "SleepWell Designs," which creates ergonomic neck pillows for office workers. They wanted a unique, contoured shape offering specific lumbar support. They needed a mold that could produce pillows with consistent quality.

After researching, SleepWell Designs contacted several mold manufacturers. One quoted them $3,500 for a silicone mold with a smooth finish, suitable for an initial run of 500 units. Another offered a slightly more complex, durable plastic mold for $8,000, allowing for higher volume production (5,000+) but with a longer lead time.

SleepWell Designs also spoke with Jia Yu Textile Factory. Jia Yu provided a detailed quote for a custom mold designed for their specific needs, highlighting features like consistent filling and durability suitable for their target market. They discussed material options and lead times, ensuring the solution aligned with SleepWell's production goals and budget.

Why Choose Jia Yu Textile Factory for Your Custom Pillow Mold?

When you're investing in a custom mold, you want a reliable partner. Jia Yu Textile Factory offers more than just manufacturing; they provide a comprehensive solution focused on quality and partnership.

- Expertise in Textile Mold Manufacturing: Jia Yu understands the nuances of molds used for filling materials, ensuring your design is feasible and the final product meets quality standards.

- Quality Materials & Craftsmanship: They utilize high-quality materials to build durable molds that produce consistent, high-quality pillows over many uses. Precision manufacturing ensures your design is accurately translated.

- Customized Solutions: From simple shapes to complex contours, Jia Yu works closely with clients to bring their unique vision for the perfect neck pillow to life.

- Reliable Production & Support: They offer competitive pricing based on realistic volume estimates and provide support throughout the mold manufacturing and production process.

- Focus on Product Advantages: The molds produced by Jia Yu are designed not just to look good, but to enhance the performance and comfort of the final product. This focus translates into pillows that better support the neck, potentially reducing fatigue and improving sleep quality for the end-user.

Conclusion

Determining the cost of a custom neck pillow mold involves understanding your specific requirements and working with a qualified manufacturer. By considering factors like design complexity, material, size, and production volume, you can get a better idea of where you might expect to spend. Don't hesitate to request quotes from multiple suppliers, including specialized partners like Jia Yu Textile Factory, to find the best fit for your project. Investing in a well-designed, high-quality mold is a crucial step towards creating exceptional, comfortable neck pillows that your customers will love.

Expanded Knowledge:

Hello, dear friends! Today, I'm going to talk about the customized neck pillow molds at Jin Yu Textile Factory. If you're looking for high-quality neck pillows but can't find a suitable mold, then this article is for you!

Understanding Customized Neck Pillow Molds

First of all, let's understand what customized neck pillow molds are. These are special molds used for making neck pillows, which can be custom-made according to your specific requirements. The advantages of using customized molds are obvious. They can ensure the uniqueness and comfort of each pillow, meeting different needs and preferences.

Why Choose Jin Yu Textile Factory for Customized Neck Pillow Molds?

Now, let's talk about why you should choose Jin Yu Textile Factory for your customized neck pillow mold needs. Here are some key reasons:

-

High-Quality Materials: Jin Yu Textile Factory uses high-quality materials to ensure the durability and stability of the molds. This means that your neck pillows will be long-lasting and comfortable.

-

Experienced Team: Our factory has a professional team with extensive experience in manufacturing customized neck pillow molds. They can provide you with professional design and technical support to ensure the accuracy and quality of your molds.

-

Customization Options: We offer a wide range of customization options to meet your specific needs. Whether you need a simple design or a complex structure, we can help you create it.

-

Fast Turnaround Time: We understand the importance of time, especially in today's fast-paced world. That's why we strive to provide you with a fast turnaround time for your orders. Once you place an order, we will do our best to deliver it to you as soon as possible.

-

Competitive Prices: While maintaining high quality, we also offer competitive prices to ensure that you get the best value for your money. You won't have to compromise on quality when choosing us.

How Much Does It Cost to Make Customized Neck Pillow Molds?

Now, let's answer your question: How much does it cost to make customized neck pillow molds? The cost depends on several factors, including the complexity of the design, the size of the mold, and the materials used. Generally speaking, the cost can range from a few hundred to several thousand dollars.

To get an accurate quote, please visit our website or contact our sales team. We will be happy to provide you with a detailed quote based on your specific requirements.

Case Example: Customized Neck Pillow Molds for a Hotel

Let me share with you an example of how Jin Yu Textile Factory can help you create customized neck pillow molds for a hotel. Imagine a luxurious hotel with high-quality客户服务. The hotel owner wants to provide guests with the most comfortable and unique neck pillows possible.

To achieve this, the hotel owner contacts Jin Yu Textile Factory. We work closely with the hotel to understand their specific requirements and preferences. We design a custom mold that meets the needs of the hotel's guests, ensuring both comfort and uniqueness.

As a result, the hotel now offers guests the most comfortable and unique neck pillows in the industry. This has helped the hotel improve guest satisfaction and loyalty, leading to increased revenue.

Product Advantages of Customized Neck Pillow Molds

Now, let's talk about the advantages of customized neck pillow molds. Here are some key points:

-

Comfort: Customized molds allow for the precise shaping of the pillow, ensuring maximum comfort for the user. Whether you prefer a soft or hard pillow, we can create a mold that suits your needs.

-

Uniqueness: With customized molds, each pillow is unique. This means that guests can enjoy a one-of-a-kind sleeping experience, making the hotel or product more appealing.

-

Durability: Customized molds are made from high-quality materials that are resistant to wear and tear. This ensures that the pillows last for a long time, providing value for money for the hotel or business.

-

Customization: We offer a wide range of customization options, allowing you to create molds that meet your specific requirements. Whether you need a simple design or a complex structure, we can help you create it.

-

Cost-Effectiveness: While maintaining high quality, customized molds are also cost-effective. By using our services, you can create high-quality pillows without having to invest in expensive equipment or materials.

Conclusion

In conclusion, customized neck pillow molds are an excellent way to enhance the comfort and uniqueness of your products. Jin Yu Textile Factory is committed to providing high-quality molds that meet your specific requirements. We offer competitive prices and fast turnaround times to ensure that you get the best value for your money.

If you're looking for customized neck pillow molds for your business or project, please don't hesitate to contact us. We look forward to working with you and helping you create the perfect neck pillows for your customers.

FAQs

-

How long does it take to make a customized neck pillow mold? The production time for a customized neck pillow mold typically ranges from 2 to 4 weeks, depending on the complexity of the design and the size of the mold.

-

Can you provide samples of your customized neck pillow molds? Yes, we can provide samples of our customized neck pillow molds for you to review and approval before placing an order.

-

What materials do you use to make customized neck pillow molds? We use high-quality materials such as high-grade plastics, metals, and composites to ensure the durability and stability of the molds.

-

Is your customized neck pillow mold suitable for commercial use? Absolutely! Our customized neck pillow molds are designed for commercial use and can be used in various industries such as hotels, resorts, airlines, and more.

-

Can you help with the design and development of customized neck pillow molds? Yes, we have a team of experienced engineers and designers who can work with you to develop and refine the design of your customized neck pillow molds according to your specific requirements.

By choosing Jin Yu Textile Factory for your customized neck pillow mold needs, you're making a wise investment that will bring long-term benefits to your business or project. We look forward to working with you and helping you create the perfect neck pillows for your customers.